2017 High quality Juice Blending Tank - Jacket reactor – Nanquan Chemical

2017 High quality Juice Blending Tank - Jacket reactor – Nanquan Chemical Detail:

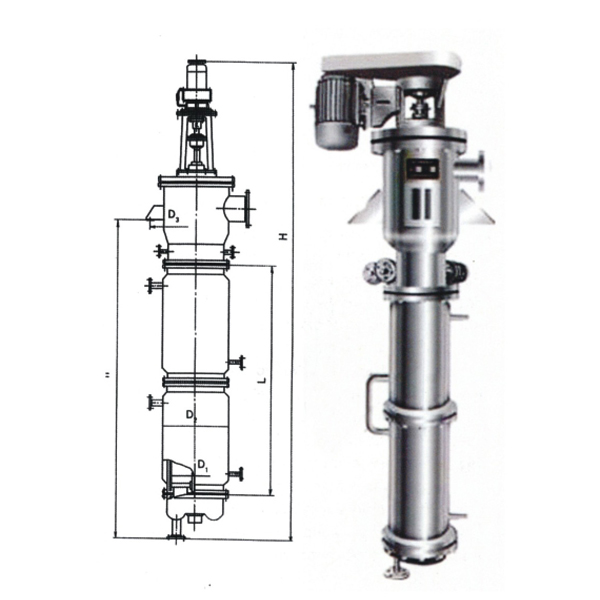

The Reactor Vessel is made of stainless steel, Which is used in food, pharmaceutical and chemical industry and also have the wide-ranging application in petrochemical industry. The equipment is manufactured precisely and polished to a mirror surface. The part of contact corrosion medium also carry on acid cleaning andpassivation.

The reaction kettle operation is allowed at certain temperature and pressure,through agitator mixes some kinds of solids or liquids in certain volumes, promotes its chemical reaction. Type of agitation usually uses paddle, anchor or frame type which ensures equal and uniform mixture in short time. Actually in order to the heat effect, it is required heat energy exchanging device.

Features :

1.Volume: 0.05-20 m3

2.Materials: SS304,SS316L,SS321

3.Seal: Mechanical Seal, Magnetic Seal.

4.Type: jacket reactor, Half-Pipe reactor

5.Heating: electric heating, steam heating, hot water heating, heat transfer oil circulation heating etc.

The main technical parameters:

|

Nominal volume(L) |

Inner pot diameter Dg(mm) |

Jacket diameter Dg(mm) |

Motor Power(KW) |

Reducer model |

Stirring speed |

Electric heating power |

|

50 |

400 |

600 |

0.6 |

M3 |

60-80 |

2KW×3 |

|

100 |

500 |

700 |

1.1 |

M4 |

60-80 |

2KW×6 |

|

200 |

600 |

800 |

1.5 |

M4 |

60-80 |

3KW×6 |

|

300 |

700 |

900 |

2.2 |

M6 |

60-80 |

3KW×6 |

|

500 |

900 |

1100 |

2.2 |

M6 |

60-80 |

4KW×9 |

|

1000 |

1200 |

1400 |

4 |

M8 |

60-80 |

4KW×12 |

|

2000 |

1400 |

1600 |

5.5 |

M8 |

60-80 |

5KW×15 |

|

3000 |

1600 |

1800 |

7.5 |

M8 |

60-80 |

5KW×15 |

|

4000 |

1700 |

1900 |

7.5 |

M10 |

60-80 |

5KW×15 |

|

5000 |

1800 |

2000 |

7.5 |

M10 |

60-80 |

5KW×18 |

Product detail pictures:

Related Product Guide:

API Heat Transfer Restructures Business Units After ThermaSys Merger | Spraying Drying Machine

Fact Check: Sorry Mr Amitabh Bachchan, Nasa doesn’t have a rain cloud generator | Home Use Heater

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for 2017 High quality Juice Blending Tank - Jacket reactor – Nanquan Chemical , The product will supply to all over the world, such as: Jeddah , Lisbon , Philippines , Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!