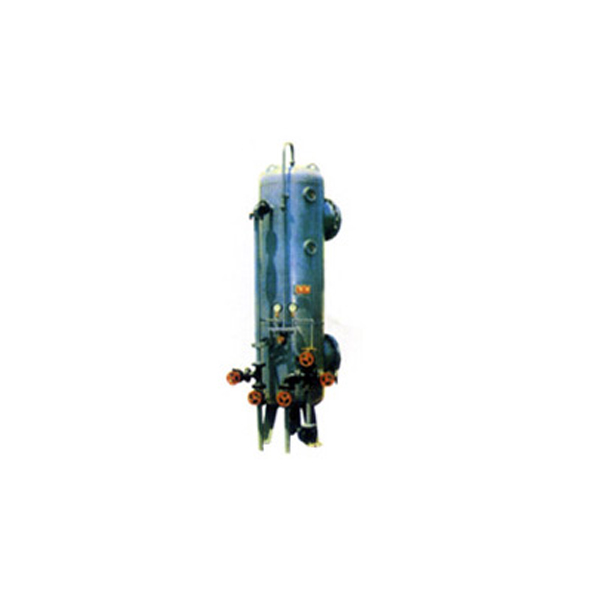

Best-Selling Szg Double Conical Vacuum Dryer - Lon exchanger – Nanquan Chemical

Best-Selling Szg Double Conical Vacuum Dryer - Lon exchanger – Nanquan Chemical Detail:

Widely used in the preparation of various industrial and civil demineralized water, such as boiler water, lotion in heating and air conditioning systems, textile printing and dyeing, paper making, laundry, bathing, food processing, high quality water and other fields. The treatment flow rate is from 0.3 to several tens of tons per hour.

Features:

Easy to manage: Users don’t need expertise. Equipment is really “fully automated”; all management regularly add brine

Continuous outflow: two tank systems, one for production and one for preparation, continuous water supply within 24 hours.

Controlled flow: Ensure economical operation.

Upstream regeneration: Regeneration uses a countercurrent process, regenerating and washing with demineralized water to achieve low salt consumption and high quality effluent flow.

Simple maintenance: low failure rate.

Parameters:

|

specification |

Work pressure(MPa) |

Operating temperature℃ |

Applicable boiler evaporation(t/T) |

Outer diameter × length(mm) |

weight(kg) |

Remarks |

|

φ219 |

0.8 |

174.5 |

0.5 |

219×1156 |

78 |

In addition to the above specifications, there are a variety of specifications available for users to choose from. If special specifications are required, they can be designed and manufactured. |

|

φ325 |

1 |

1 |

341×1410 |

142 |

||

|

φ350 |

2 |

366×1545 |

150 |

|||

|

φ500 |

1.3 |

194 |

4 |

516×2016 |

325 |

|

|

φ600 |

6 |

620×2280 |

558.83 |

|||

|

φ1000 |

1.6 |

203 |

10 |

1028×1818 |

1380.28 |

Product detail pictures:

Related Product Guide:

API Heat Transfer Restructures Business Units After ThermaSys Merger | Spraying Drying Machine

How record prices for a rare Scotch whisky sparked a ‘liquid gold’ rush | Spraying Drying Machine

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for Best-Selling Szg Double Conical Vacuum Dryer - Lon exchanger – Nanquan Chemical , The product will supply to all over the world, such as: Botswana , Brunei , Miami , With top quality products, great after-sales service and warranty policy, we win trust from many overseas partner, many good feedbacks witnessed our factory's growth. With full confidence and strength, welcome customers to contact and visit us for future relationship.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!