Europe style for Nozzle For Fractionating Tower - Machine filter – Nanquan Chemical

Europe style for Nozzle For Fractionating Tower - Machine filter – Nanquan Chemical Detail:

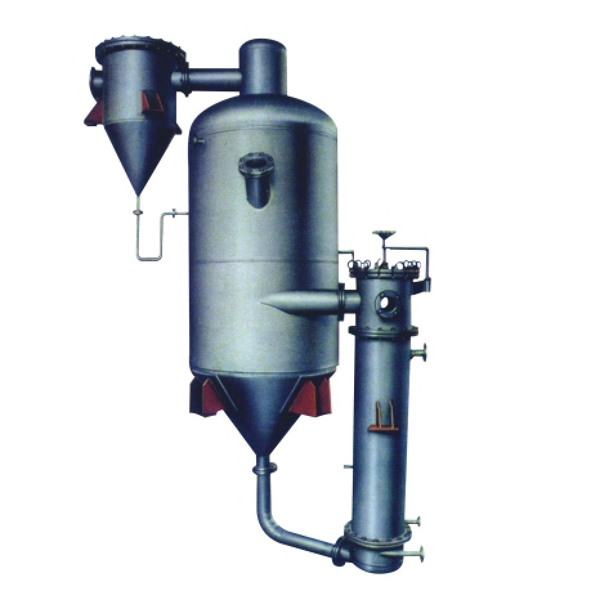

The filter is generally placed in front of the pressure vessel to remove fine particles with a turbidity above 1 degree to meet the requirements of the subsequent process water; sometimes it is also placed at the end of the entire water system to prevent small particles (such as broken resin) ) Enter the finished water.

The outer casing is made of high-quality stainless steel, the filter adopts a molded filter, the liquid is filtered by pressure, and remains on the filter. The filtrate flows out of the filter, which can effectively remove impurities, sediment and suspended matter in the water, and bacteria. Molded filters are: fabrics, screens, filters, sintered filter tubes, wound filters, meltblown filters, microporous filters and multi-purpose filters. Due to the different filters, the pore size of the filter is also different. The precision filter is a filter between the sand filter (coarse) and the filter, and the filter pore size is generally between 0.01 and 120 um. For the same form of filter, it is divided into different models according to their size.

application

1. Food industry: fine filtration of space water, mineral water, beverages, wine clarification and filtration processes.

2. Pharmaceutical industry: sterile water, oral, infusion and water injection.

Electronics industry: water production semiconductor, instrument, picture tube and other production plants, washing water filter rods.

Chemical industry: organic solvents, esters, alcohols, acids, alkalis and other chemicals, oil purification.

5. Oil industry: oilfield water injection preparation.

6. Environmental protection, electroplating wastewater, printing waste, pharmaceutical waste and other industrial wastewater treatment.

7. Seawater, brackish water desalination water treatment, hotel, apartment water treatment.

8. Precision filters are often used as safety filters for electrodialysis, ion exchange, and safety filter reverse osmosis units.

Parameters:

|

specification |

Work pressure(MPa) |

Operating temperature℃ |

Applicable boiler evaporation(t/T) |

Outer diameter × length(mm) |

weight(kg) |

Remarks |

|

φ219 |

0.8 |

174.5 |

0.5 |

219×1156 |

78 |

In addition to the above specifications, there are a variety of specifications available for users to choose from. If special specifications are required, they can be designed and manufactured. |

|

φ325 |

1 |

1 |

341×1410 |

142 |

||

|

φ350 |

2 |

366×1545 |

150 |

|||

|

φ500 |

1.3 |

194 |

4 |

516×2016 |

325 |

|

|

φ600 |

6 |

620×2280 |

558.83 |

|||

|

φ1000 |

1.6 |

203 |

10 |

1028×1818 |

1380.28 |

Product detail pictures:

Related Product Guide:

Taking the corn plunge in the West — gradually | Stainless Steel Holding Tanks

Popular Alexa and Google enabled smart plugs drop to $6, an all-time low | Home Use Heater

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of Europe style for Nozzle For Fractionating Tower - Machine filter – Nanquan Chemical , The product will supply to all over the world, such as: Greece , Hungary , Turin , We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.