Factory best selling Heidolph Rotary Evaporator - Tubular heat exchanger – Nanquan Chemical

Factory best selling Heidolph Rotary Evaporator - Tubular heat exchanger – Nanquan Chemical Detail:

The spiral plate heat exchanger is a high-efficiency heat exchange device suitable for steam-vapor, vapor-liquid, liquid-liquid, convection heat transfer. It is suitable for chemical, petroleum, solvent, pharmaceutical, food, light industry, textile, metallurgy, Rolling steel, coking and other industries. According to the structure, it can be divided into non-removable (i type) and detachable (ii type, iii type) spiral plate heat exchangers.

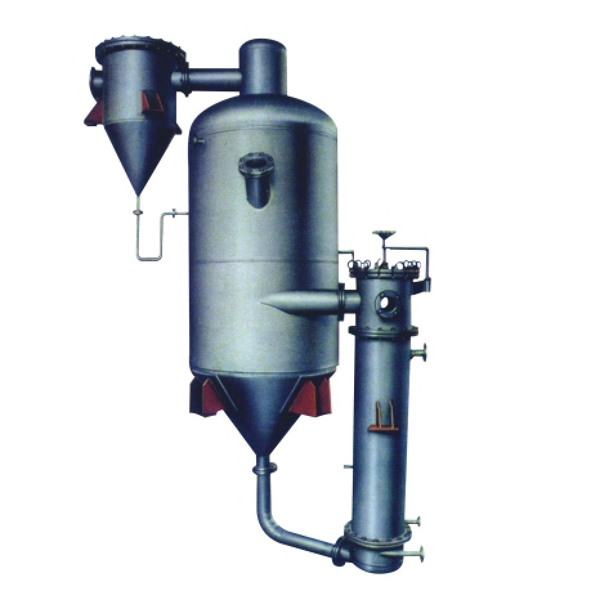

The tube-type condenser produced by our company is divided into carbon steel tube type condenser, stainless steel tube type condenser and carbon steel and stainless steel mixed tube type condenser according to the material, which are divided into fixed tube plate type according to the form. Floating head type, U-tube heat exchanger, divided into single tube, double tube and multi tube according to structure. The heat transfer area is 0.5~500 square meters, which can be customized according to user needs.

The main technical parameters:

|

Nominal diameter |

Number of tubes |

Number of pipes |

Heat exchange area Nominal value/Calculated |

Cross-sectional area of the tube path, flow rate m/hr at a flow rate of 0.5 m/sec |

Nominal pressure |

|||||

|

Pipe length(m) |

Carbon steel pipe(φ25×2.5) |

|||||||||

|

5000 |

2000 |

3000 |

4000 |

6000 |

stainless steel(φ25×2) |

|||||

|

159 |

Ⅰ |

14 |

1.5/1.62 |

2/2.17 |

3/3.27 |

|

|

0.0044/0.0049 |

7.92/8.82 |

0.25 |

|

219 |

Ⅰ |

26 |

3/3.00 |

4/4.02 |

6/6.07 |

8/8.11 |

|

0.0082/0.0090 |

14.76/16.20 |

0.6 |

|

|

Ⅱ |

26 |

3/3.00 |

4/4.02 |

6/6.06 |

8/8.11 |

|

0.0041/0.0045 |

7.38/8.10 |

1 |

|

273 |

Ⅰ |

44 |

5/5.08 |

7/6.18 |

10/10.26 |

14/13.72 |

21/20.63 |

0.0138/0.0152 |

24.84/27.36 |

1.6 |

|

|

Ⅱ |

40 |

5/4.62 |

6/6.19 |

9/9.33 |

12/12.47 |

19/18.76 |

0.0063/0.0069 |

11.34/12.42 |

2.5 |

|

325 |

Ⅰ |

60 |

7/6.93 |

9/9.28 |

14/14.00 |

19/18.71 |

28/28.13 |

0.0188/0.0208 |

33.84/37.44 |

0.6 |

|

|

Ⅱ |

56 |

6/6.47 |

9/8.66 |

13/13.06 |

17/17.46 |

26/26.26 |

0.0088/0.0097 |

15.84/17.46 |

1 |

|

400 |

Ⅰ |

119 |

14/13.74 |

18/18.41 |

28/27.76 |

37/37.10 |

55/55.8 |

0.0374/0.0412 |

67.32/74.16 |

1.6 |

|

|

Ⅱ |

110 |

13/12.70 |

17/17.02 |

26/25.66 |

34/34.20 |

50/51.58 |

0.0173/0.0190 |

31.14/34.20 |

2.5 |

|

500 |

Ⅰ |

185 |

|

|

45/4.15 |

55/57.68 |

85/86.74 |

0.0581/0.0641 |

104.58/115.38 |

|

|

|

Ⅱ |

180 |

|

|

40/41.99 |

55/57.68 |

85/86.74 |

0.0283/0.0312 |

50.94/46.16 |

|

|

600 |

Ⅰ |

169 |

|

|

60/62.05 |

85/83.88 |

125/126.13 |

0.0845/0.0932 |

152.10/167.76 |

|

|

|

Ⅱ |

266 |

|

|

60/62.05 |

80/82.94 |

125/14.72 |

0.0418/0.0461 |

75.24/82.98 |

|

|

700 |

Ⅰ |

379 |

|

|

90/88.41 |

120/118.17 |

175/177.71 |

0.0091/0.1313 |

214.38/236.34 |

|

|

|

Ⅱ |

358 |

|

|

85/83.51 |

110/111.62 |

165/167.86 |

0.0562/0.0620 |

101.16/111.60 |

|

|

800 |

Ⅰ |

511 |

|

|

120/119.20 |

160/159.16 |

240/239.60 |

0.1605/0.1770 |

288.90/318.60 |

|

|

|

Ⅱ |

488 |

|

|

115/113.82 |

150/152.16 |

230/228.81 |

0.0767/0.0845 |

138.06/152.10 |

|

|

900 |

Ⅰ |

649 |

|

|

150/151.39 |

200/202.36 |

305/304.3 |

0.2039/0.2248 |

367.02/404.46 |

|

|

|

Ⅱ |

630 |

|

|

145/146.96 |

195/196.44 |

295/295.40 |

0.0990/0.1091 |

178.20/196.38 |

|

|

1000 |

Ⅰ |

805 |

|

|

185/187.78 |

250/251.00 |

375/377.45 |

0.2829/0.2788 |

455.22/501.84 |

|

|

|

Ⅱ |

792 |

|

|

185/184.75 |

245/246.95 |

370/371.36 |

1.1244/0.1374 |

223.92/246.96 |

|

Product detail pictures:

Related Product Guide:

SWEP Inc.: Heat Pump Heat Exchanger | 2012-06-04 | Cone Coffee Filter

Global Dust Control Systems Market By Region, Vendors, SWOT And PESTEL Analysis Forecast to 2028 | Stainless Steel Holding Tanks

The customer satisfaction is our primary goal. We uphold a consistent level of professionalism, quality, credibility and service for Factory best selling Heidolph Rotary Evaporator - Tubular heat exchanger – Nanquan Chemical , The product will supply to all over the world, such as: Singapore , Birmingham , Spain , We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.