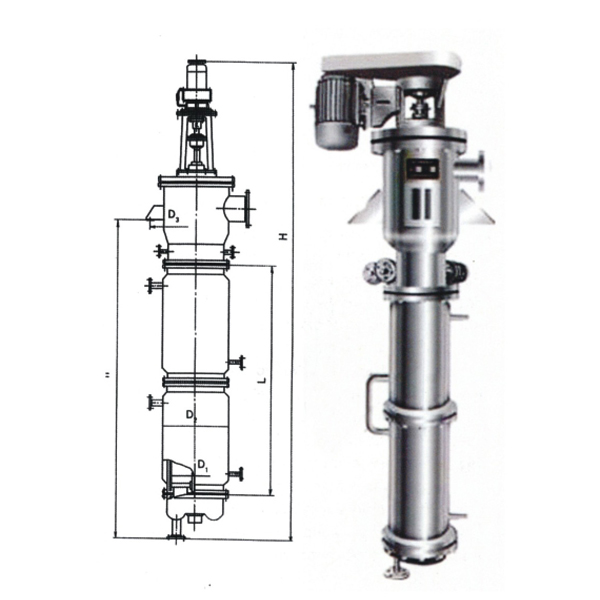

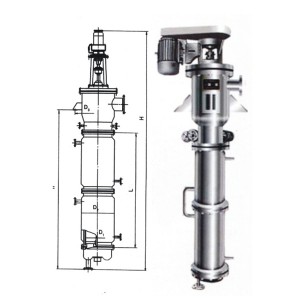

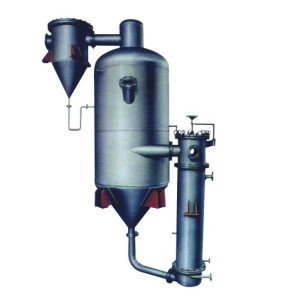

LG series centrifugal scraper film evaporator

Equipment introduction:

Centrifugal scraper film evaporator adopts international advanced technology and has a leading position in the field of scraped film evaporator. This equipment has been used as the mainframe of scraper vacuum enfining unit and won the scientific and technological progress of the State Administration of Medicine. And other awards.

Features:

This equipment adopts centrifugal sliding groove rotor, which is the latest foreign structural evaporator, in flow In a very small case, a film can be formed, and the sludge in the treatment liquid adhering to the inner wall surface of the evaporation section of the cylinder can be quickly moved by the movable plate, and the evaporation amount can be increased by 40%-69 compared with the fixed-blade squeegee evaporator. %, it has the following performance and features:

1. High heat transfer coefficient, large evaporation capacity, evaporation strength up to 200kg/m2-hr, thermal efficiency the rate is high.

2, The material heating time is short, about 1 second to 10 seconds, and work under important vacuum conditions, It is more beneficial to heat sensitive materials, keeping all kinds of components without any decomposition and ensuring product quality.

3, Adapt to a wide range of viscosity changes, high and low viscosity materials can be processed, material viscosity can be as high as 10 wan Libo (CP)。

4. Change the direction of rotation of the scraper groove to adjust the time of the material in the evaporator.

5. The inner wall of the evaporation section cylinder is precision boring and polished, and the surface is not easy to produce coking and scaling.

6, Easy to operate, easy to adjust product indicators, under closed conditions, can be self-controlled for continuity produce.

7. The equipment has small floor space, simple structure, convenient maintenance and easy cleaning.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.