OEM Customized Tube Coil Heat Exchanger - Drying equipment – Nanquan Chemical

OEM Customized Tube Coil Heat Exchanger - Drying equipment – Nanquan Chemical Detail:

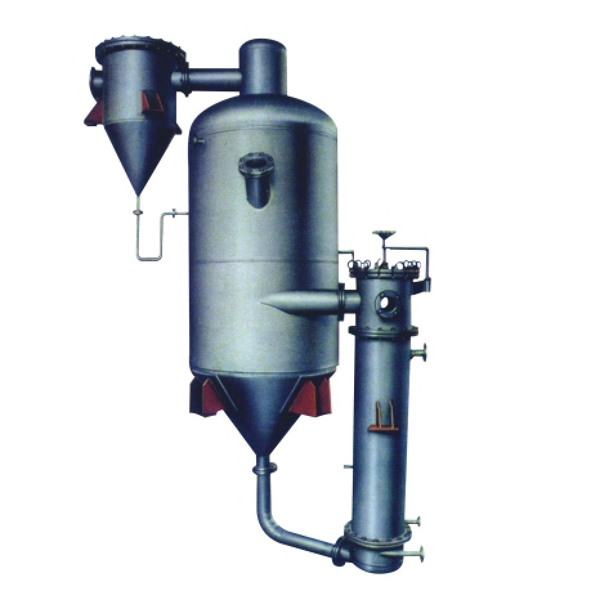

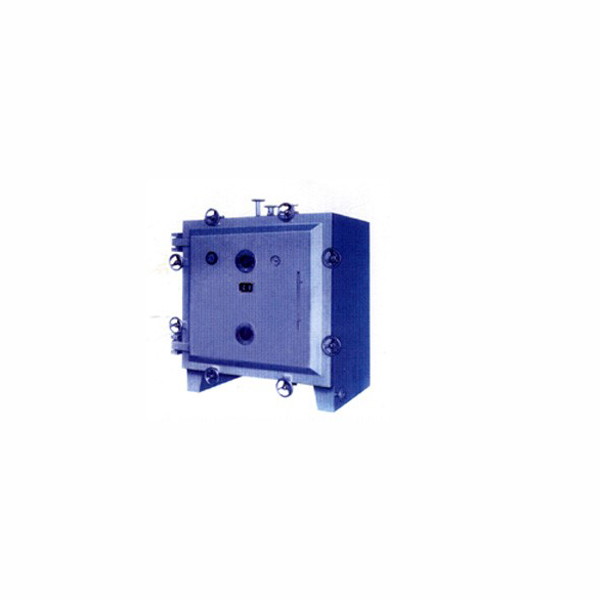

The drying equipment is heated by heating the equipment jacket, the inner tank is continuously tumbling and stirred, and the equipment liner is vacuum-dehumidified to achieve further drying and mixing of the materials. The dryers produced by the company are widely used in the chemical, pharmaceutical, fuel, food and other industries.

We are a professional manufacturer of high quality Drying equipment. We welcome customers to cooperate and negotiate.

Equipment Parameter Table (YZG/FZG) Series:

|

Name/specification/parameter |

YZG-600 |

YZG-1000 |

YZG-1400 |

FZG-15 |

|

Drying box internal size(mm) |

φ600×975 |

φ1000×1527 |

φ1400×2054 |

1500×1400×1220 |

|

Drying box external size(mm) |

1135×800×1020 |

1693×1190×1500 |

2386×1675×1920 |

1513×1924×2060 |

|

Drying layer |

4 |

6 |

8 |

8 |

|

Interlayer distance(mm) |

81 |

102 |

102 |

122 |

|

Baking tray size(mm) |

310×600×45 |

640×460×45 |

460×640×45 |

160×640×45 |

|

Baking tray |

4 |

12 |

32 |

32 |

|

Use internal force in the drying tube(MPa) |

≥0.784(8kg/m2h) |

≥0.784 |

≥0.784 |

≥0.784 |

|

Drying rack use temperature℃ |

-185 |

-185 |

-185 |

-185 |

|

No-load vacuum in the box(MPa) |

-0.1 |

-0.1 |

-0.1 |

-0.1 |

|

At -0.1 MPa, heating temperature 110 ° C, water vaporization rate(kg/m2h) |

7.2 |

7.2 |

7.2 |

7.2 |

|

Vacuum pump model power when using condenser |

2X-15A.2.2Kw |

2X-30A.3Kw |

2X-70A.5.5Kw |

2X-70A.5.5Kw |

|

Vacuum pump model power without condenser |

JZJS-70.7Kw |

JZJS-70.7Kw |

JZJS-70.7Kw |

JZJS-70.7Kw |

|

Drying box weight(kg) |

250 |

800 |

1400 |

2100 |

Product detail pictures:

Related Product Guide:

Wabash National (WNC) to pay $0.08 on Jul 25, 2019; Ducommun (DCO)’s Sentiment Is 1.11 | Home Use Heater

Here’s what to do when your cat pees on your stuff | Home Use Heater

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for OEM Customized Tube Coil Heat Exchanger - Drying equipment – Nanquan Chemical , The product will supply to all over the world, such as: Singapore , Portugal , Macedonia , Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.