OEM Manufacturer Chilled Cooling Coil Heat Exchanger - Fermenter – Nanquan Chemical

OEM Manufacturer Chilled Cooling Coil Heat Exchanger - Fermenter – Nanquan Chemical Detail:

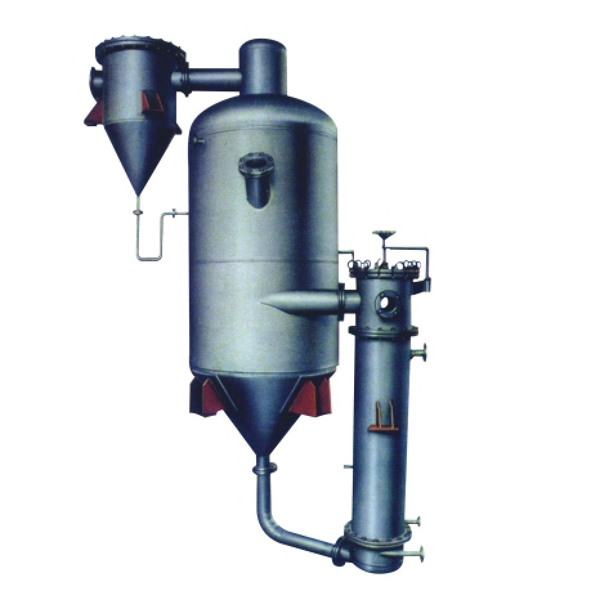

Fermentation equipment is a reaction device widely used for the growth of microorganisms. In the fermenter, various microorganisms are grown in a suitable environment, metabolism and fermentation products. Fermentation equipment has been widely used in the pharmaceutical, MSG, brewing, enzyme preparation, pigment, food and other industries.

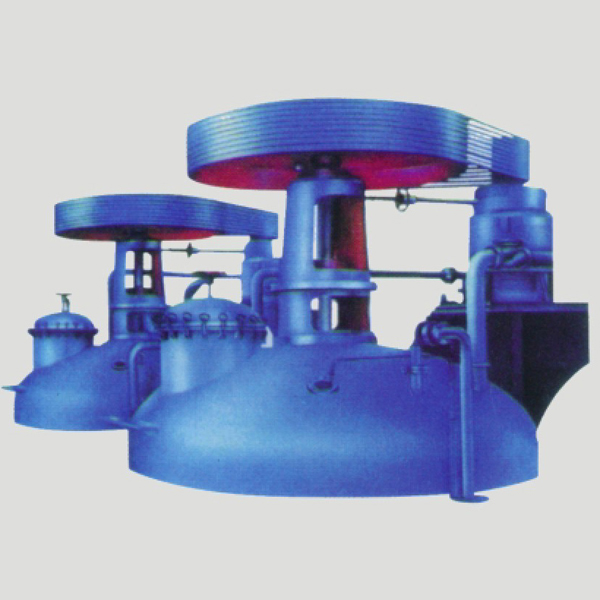

The agitator is the main device in the fermentation equipment. By mixing the liquid, the fresh culture components, air and mycelium are thoroughly mixed to achieve mass transfer and heat transfer. At present, there are three basic forms of the agitator: flat leaf (straight leaf) , curved leaves, arrows. Curved leaves are used in the equipment provided by the company. The curved worm wheel agitator has a shearing effect on the fermentation broth, and the fermentation broth has radial and axial flow. Compared with the straight-blade worm gear agitator, the power consumption of the curved blade agitator is small under the same diameter, rotation speed, leaf width and the like, but the effect is very good, and has been generally adopted in China.

Parameter:

|

Nominal volume(m3) |

Cylinder diameter(DNmm) |

Barrel height(Hmm) |

Heat exchange area(M2) |

Mixing shaft speed(r.p.m) |

Mixing shaft power(KW) |

|

10 |

1800 |

3800 |

14 |

160-260 |

17-22 |

|

15 |

2000 |

4800 |

18 |

166-260 |

22-30 |

|

20 |

2200 |

5000 |

22 |

160-260 |

30-37 |

|

30 |

2400 |

6600 |

34 |

150-250 |

45-55 |

|

40 |

2600 |

7500 |

45 |

150-250 |

55-75 |

|

50 |

2800 |

8000 |

58 |

150-250 |

55-90 |

|

60 |

3000 |

8300 |

65 |

150-150 |

65-115 |

|

75 |

3200 |

8800 |

84 |

150-250 |

90-145 |

|

100 |

3600 |

9400 |

114 |

150-250 |

120-125 |

|

150 |

4200 |

10800 |

165 |

150-250 |

165-275 |

|

200 |

4600 |

11500 |

220 |

140-240 |

215-316 |

Product detail pictures:

Related Product Guide:

Here’s what to do when your cat pees on your stuff | Home Use Heater

Diesel Exhaust Fluid Market Potential Growth Opportunities, Competitive Landscape, Trends and Forecast 2018-2026 | Home Use Heater

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for OEM Manufacturer Chilled Cooling Coil Heat Exchanger - Fermenter – Nanquan Chemical , The product will supply to all over the world, such as: Sao Paulo , Guatemala , New Delhi , As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly