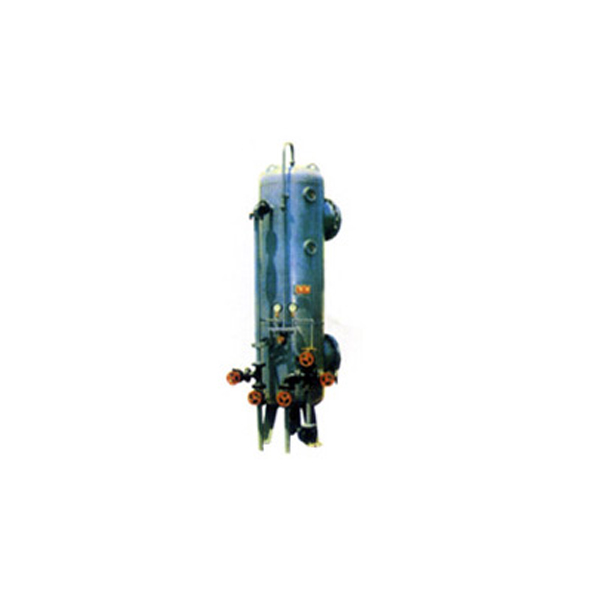

OEM/ODM Factory Titanium Coil Heat Exchanger - Spiral plate heat exchanger – Nanquan Chemical

OEM/ODM Factory Titanium Coil Heat Exchanger - Spiral plate heat exchanger – Nanquan Chemical Detail:

Spiral plate heat exchanger is suitable for chemical, petroleum, pharmaceutical, food, solvent, light industry, textile, metallurgy, steel rolling, coking and other industries.

It is suitable for steam-vapor, vapor-liquid, liquid-liquid convection heat transfer, waste heat recovery, and can also be used for steam condensation and liquid evaporation heat transfer.

Features

1. The machine is made up of two coils to form two uniform spiral channels. The two heat transfer media can carry out full countercurrent flow, which greatly enhances the heat transfer effect. Even two small temperature difference media can reach

To the ideal heat transfer effect.

2. The connecting pipe on the casing adopts a tangential structure, and the local resistance is small. Since the curvature of the spiral passage is uniform, the liquid flows in the equipment without large steering, and the total resistance is small, so that the design can be improved.

The flow rate gives it a high heat transfer capacity.

3. The end face of the spiral passage of the type I non-removable spiral plate heat exchanger is welded and sealed, thus having a high sealing property.

4. The structural principle of the detachable spiral plate heat exchanger is basically the same as that of the non-removable heat exchanger, but one of the channels can be disassembled and cleaned, especially the heat exchange with viscous and precipitated liquid.

5. The structure principle of the detachable spiral plate heat exchanger is basically the same as that of the non-removable heat exchanger, but the two channels can be disassembled and cleaned, and the scope of application is wide.

6, spiral plate heat exchanger according to the nominal pressure can be divided into PNO.6, 1.0.1.6, 2.5MPa (refers to the maximum working pressure that a single channel can withstand). According to the material, it can be divided into carbon steel and stainless steel. Users can choose according to the actual process conditions.

Product detail pictures:

Related Product Guide:

Steve Carell on Switching to Dramas, Welcome to Marwen & Why He Bought a General Store in Massachusetts | Home Use Heater

Here are seven of the basic rules for getting your ducts in a row | Spraying Drying Machine

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for OEM/ODM Factory Titanium Coil Heat Exchanger - Spiral plate heat exchanger – Nanquan Chemical , The product will supply to all over the world, such as: Luxembourg , Sydney , Sri Lanka , Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So you should feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we are going to surely present you with the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we'll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we're here to welcome your inquiries for any of our merchandise and service.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!