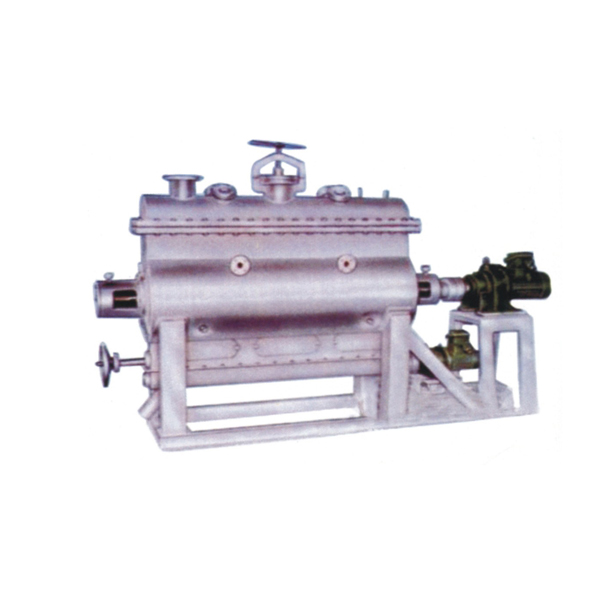

Renewable Design for Vacuum Ethanol Distillation - Spiral plate heat exchanger – Nanquan Chemical

Renewable Design for Vacuum Ethanol Distillation - Spiral plate heat exchanger – Nanquan Chemical Detail:

Spiral plate heat exchanger is suitable for chemical, petroleum, pharmaceutical, food, solvent, light industry, textile, metallurgy, steel rolling, coking and other industries.

It is suitable for steam-vapor, vapor-liquid, liquid-liquid convection heat transfer, waste heat recovery, and can also be used for steam condensation and liquid evaporation heat transfer.

Features

1. The machine is made up of two coils to form two uniform spiral channels. The two heat transfer media can carry out full countercurrent flow, which greatly enhances the heat transfer effect. Even two small temperature difference media can reach

To the ideal heat transfer effect.

2. The connecting pipe on the casing adopts a tangential structure, and the local resistance is small. Since the curvature of the spiral passage is uniform, the liquid flows in the equipment without large steering, and the total resistance is small, so that the design can be improved.

The flow rate gives it a high heat transfer capacity.

3. The end face of the spiral passage of the type I non-removable spiral plate heat exchanger is welded and sealed, thus having a high sealing property.

4. The structural principle of the detachable spiral plate heat exchanger is basically the same as that of the non-removable heat exchanger, but one of the channels can be disassembled and cleaned, especially the heat exchange with viscous and precipitated liquid.

5. The structure principle of the detachable spiral plate heat exchanger is basically the same as that of the non-removable heat exchanger, but the two channels can be disassembled and cleaned, and the scope of application is wide.

6, spiral plate heat exchanger according to the nominal pressure can be divided into PNO.6, 1.0.1.6, 2.5MPa (refers to the maximum working pressure that a single channel can withstand). According to the material, it can be divided into carbon steel and stainless steel. Users can choose according to the actual process conditions.

Product detail pictures:

Related Product Guide:

Quietest Space Heaters From Consumer Reports’ Tests | Bar And Plate Heat Exchanger

Comparing of Ryerson Holding Corporation (RYI) and Chart Industries Inc. (NASDAQ:GTLS) | Bar And Plate Heat Exchanger

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto "High High quality, Competitive Rate, Fast Service" for Renewable Design for Vacuum Ethanol Distillation - Spiral plate heat exchanger – Nanquan Chemical , The product will supply to all over the world, such as: Bahrain , Argentina , Uruguay , With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!