Special Design for Centrifuge Separator - Jacket reactor – Nanquan Chemical

Special Design for Centrifuge Separator - Jacket reactor – Nanquan Chemical Detail:

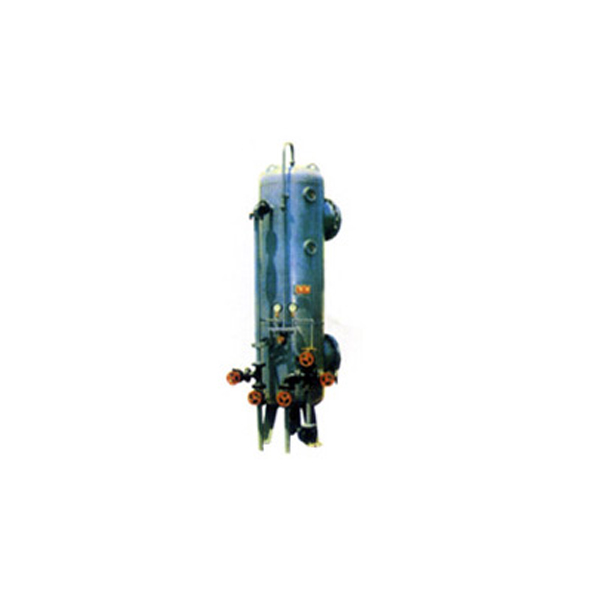

The Reactor Vessel is made of stainless steel, Which is used in food, pharmaceutical and chemical industry and also have the wide-ranging application in petrochemical industry. The equipment is manufactured precisely and polished to a mirror surface. The part of contact corrosion medium also carry on acid cleaning andpassivation.

The reaction kettle operation is allowed at certain temperature and pressure,through agitator mixes some kinds of solids or liquids in certain volumes, promotes its chemical reaction. Type of agitation usually uses paddle, anchor or frame type which ensures equal and uniform mixture in short time. Actually in order to the heat effect, it is required heat energy exchanging device.

Features :

1.Volume: 0.05-20 m3

2.Materials: SS304,SS316L,SS321

3.Seal: Mechanical Seal, Magnetic Seal.

4.Type: jacket reactor, Half-Pipe reactor

5.Heating: electric heating, steam heating, hot water heating, heat transfer oil circulation heating etc.

The main technical parameters:

|

Nominal volume(L) |

Inner pot diameter Dg(mm) |

Jacket diameter Dg(mm) |

Motor Power(KW) |

Reducer model |

Stirring speed |

Electric heating power |

|

50 |

400 |

600 |

0.6 |

M3 |

60-80 |

2KW×3 |

|

100 |

500 |

700 |

1.1 |

M4 |

60-80 |

2KW×6 |

|

200 |

600 |

800 |

1.5 |

M4 |

60-80 |

3KW×6 |

|

300 |

700 |

900 |

2.2 |

M6 |

60-80 |

3KW×6 |

|

500 |

900 |

1100 |

2.2 |

M6 |

60-80 |

4KW×9 |

|

1000 |

1200 |

1400 |

4 |

M8 |

60-80 |

4KW×12 |

|

2000 |

1400 |

1600 |

5.5 |

M8 |

60-80 |

5KW×15 |

|

3000 |

1600 |

1800 |

7.5 |

M8 |

60-80 |

5KW×15 |

|

4000 |

1700 |

1900 |

7.5 |

M10 |

60-80 |

5KW×15 |

|

5000 |

1800 |

2000 |

7.5 |

M10 |

60-80 |

5KW×18 |

Product detail pictures:

Related Product Guide:

Large Circulation Attritor System | Spraying Drying Machine

Global Liquid Nitrogen Storage Tank Market Competition Analysis and SWOT Analysis to 2025 | Spraying Drying Machine

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Special Design for Centrifuge Separator - Jacket reactor – Nanquan Chemical , The product will supply to all over the world, such as: Sao Paulo , Croatia , Bahrain , Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

Wuxi Nanquan Chemical Equipment Co., Ltd. is a professional enterprise that designs and manufactures petrochemical equipment, bio-pharmaceutical equipment, mixing equipment, tower filtration, separation, purification equipment and non-standard equipment. The company has more than 200 various types of manufacturing equipment, a large number of engineering and technical personnel, professional production and service team of more than 150 people, quality assurance, reliable service, look forward to working with you.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.